The most advanced Cyclic Activated Sludge Technology

The main advantage of C-TECH is the implementation of a specially designed anaerobic selector which suppresses the growth of filamenteous bacteria that causes bulking sludge and high sludge volume indexes in the bioreactors.

Furthermore, C-TECH allows a reduction of a minimum of 50% of the treatment cycle time and therefore reactor volume in comparison of traditional SBR systems thanks to simultaneous carbon oxidation, nitrification/denitrification and the removal of biological phosphorus in one single process step. It reduces significantly investment and operational costs compared to conventional wastewater treatment systems.

More Details

Reduced energy costs by OUR (Oxygen Uptake Rate)

The process control by means of OUR (Oxygen Uptake Rate) and the automated PLC System determines time and intensity of aeration according to the degree of pollution in the wastewater, which results in economic operation of the plant.

The C-TECH technology requires a minimum of equipment, offers simple operation at low operation costs and hence is the best solution for municipal and industrial wastewater treatment plants.

The advantages of C-TECH

Sludge Volume Index

C-TECH Activated Sludge Technology generates macroflocs with low sludge volume index avoiding problems with bulking sludge resulting in extra low TSS concentration in the effluent.

Anaerobic Selector

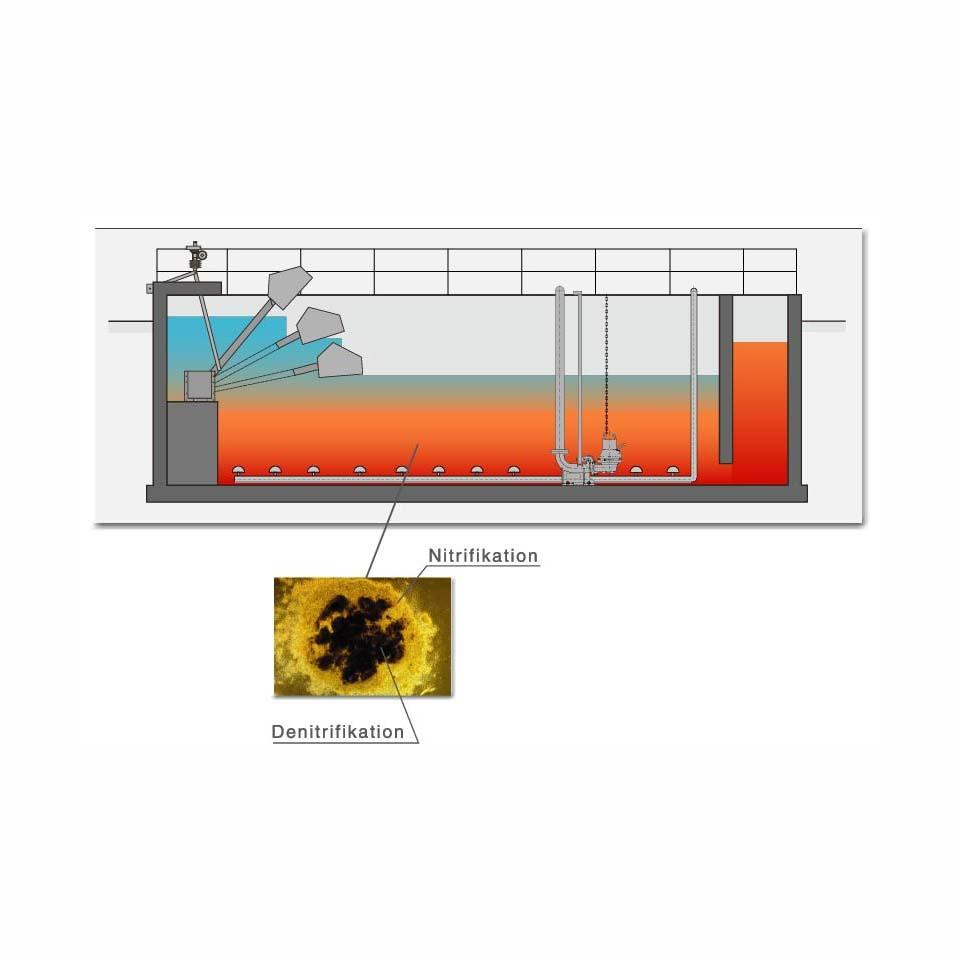

Allows co-current nitrification/denitrification in the aerated part of the tank and enhanced biological phosphorus removal.

OUR-Control

With the Oxygen Uptake Rate (OUR) control, the aeration intensity can be regulated according to the actual process demands resulting in a much more efficient system.

Savings in operating costs

Thanks to the efficiency of our system, you can reduce space requirements and operating costs such as energy and maintenance by up to 50% compared to conventional wastewater treatment plants.

The C-TECH process

In the fill and aeration cycle the water level inside the bioreactor rises from the bottom water level to the top water level.

* Operation at a lower load than the design load usually requires adaptation of the duration and intensity of the aeration cycle by OUR.

Sedimentation is initiated after the fill and aeration cycle to separate the sludge from the treated water. The sludge forms a blanket to which the activated sludge particles adhere leaving a layer of clear supernatant of treated and almost particle free treated water.

During decanting, no inflow into the bioreactor occurs. Before the end of the settling cycle it slowly moves from its parking position to the top water level and rests there until the cycle begins. Finally, the decanter withdraws the treated water by gravity above the sludge blanket.